| IN A NUTSHELL |

|

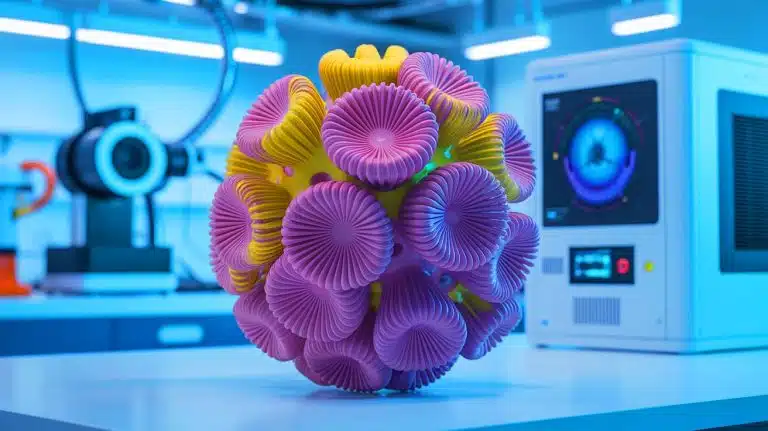

The world of energy technology is continuously evolving, and a recent breakthrough in fuel cell design is poised to make a significant impact. Researchers from the Technical University of Denmark have developed a groundbreaking ceramic fuel cell, known as the Monolithic Gyroidal Solid Oxide Cell, or “The Monolith.” This innovation leverages a coral-inspired structure and 3D printing to create a lightweight yet powerful energy source. The Monolith eliminates over 75% of the weight associated with conventional fuel cells by removing heavy metal components. This new design could revolutionize industries ranging from aerospace to renewable energy systems by providing a more efficient and sustainable power solution.

The Lightweight Revolution in Fuel Cells

Fuel cells have long been recognized for their versatility across various industries. They are integral to hydrogen-powered vehicles and serve as essential power supplies for critical infrastructures such as hospitals and data centers. Additionally, fuel cells play a crucial role in stabilizing renewable energy systems through their ability to generate power and store energy via electrolysis. However, traditional fuel cells often rely on heavy metal components, which significantly add to their weight and complexity.

The Monolithic Gyroidal Solid Oxide Cell, developed by the Technical University of Denmark, offers a transformative approach. By being entirely ceramic, the Monolith removes the need for heavy metals, resulting in a lighter and more efficient energy source. This design not only reduces the overall weight but also enhances the fuel cell’s specific power, making it suitable for applications in aerospace—a sector where weight considerations are paramount. The Monolith’s innovative architecture and lightweight nature mark a significant step forward in energy technology.

Scientists Warn: Seafood Waste Sparks US-China CO2 Battle Over Billion-Dollar Green Tech Race

Innovative Design and Manufacturing Process

The Monolith’s design is characterized by a mathematically optimized triply periodic minimal surface (TPMS), specifically a gyroid. This unique structure allows for the largest possible surface area while maintaining minimal weight. Such architecture facilitates efficient gas flow, improves heat distribution, and increases mechanical stability. The result is a fuel cell that is exceptionally powerful for its weight, capable of producing over one watt per gram.

Another notable feature of the Monolith is its simplified manufacturing process. Unlike conventional solid oxide cells, which require numerous steps and multiple materials that degrade over time, the Monolith is created in just five steps. This streamlined process eliminates the need for heavy metal components and fragile seals, enhancing the system’s durability and reliability. The combination of innovative design and efficient manufacturing makes the Monolith a compelling option for various applications.

Performance in Extreme Conditions

The Monolith fuel cell has demonstrated impressive durability, withstanding extreme conditions, including temperature swings of 180°F. This resilience is crucial for applications in demanding environments where stability and reliability are essential. Furthermore, the Monolith has been repeatedly switched between power-generating and power-storing modes without experiencing any structural failure, highlighting its robustness.

In electrolysis mode, the Monolith fuel cell produces hydrogen at a rate nearly ten times faster than standard models. This capability is particularly valuable for renewable energy systems, where efficient hydrogen production can contribute to energy storage and grid stability. The Monolith’s performance under extreme conditions and its ability to produce hydrogen efficiently underscore its potential as a game-changing technology in the energy sector.

Implications for Aerospace and Beyond

The development of the Monolith marks a significant advancement in fuel cell technology, with far-reaching implications for the aerospace industry and beyond. According to Venkata Karthik Nadimpalli, a senior researcher and corresponding author, the Monolith is the first fuel cell to demonstrate the specific power needed for aerospace applications while using a sustainable, green technology. This achievement opens the door to new possibilities in aviation, where reducing weight is a critical factor in improving efficiency and reducing emissions.

Beyond aerospace, the Monolith’s lightweight and powerful design could benefit various sectors seeking efficient and sustainable energy solutions. Its potential to stabilize renewable energy systems and its application in industries requiring reliable power sources make it a versatile and valuable innovation. As the demand for cleaner and more efficient energy technologies continues to grow, the Monolith stands out as a promising development that could reshape the future of energy.

The Monolithic Gyroidal Solid Oxide Cell represents a remarkable leap forward in fuel cell technology, offering a lightweight, efficient, and durable energy solution. Its innovative design and manufacturing process, coupled with its impressive performance in extreme conditions, make it a compelling option for a range of applications. As industries increasingly seek sustainable and efficient energy solutions, how will advancements like the Monolith shape the future of energy and technology?

Did you like it? 4.6/5 (23)

Wow, this ceramic tech sounds amazing! How soon can we expect it to hit the market? 🚀

Wow, this sounds like a game-changer for the aerospace industry! 🚀 How soon can we expect to see these fuel cells in commercial use?

Are there any downsides to using ceramics instead of metals in fuel cells?

75% weight reduction? That’s huge! How does it affect the cost?

Is it really possible for a ceramic material to withstand such extreme conditions without degrading over time? 🤔

This sounds like science fiction! Is this really feasible for large-scale production?

Thank you for sharing this exciting breakthrough! Can’t wait to see it in action. 😊

Thank you for sharing this exciting development! The potential impact on renewable energy systems is immense.

Why did it take so long for someone to think of using ceramics for this? 🤔

Isn’t ceramic more brittle than metal? How do they handle that issue?

I’m skeptical. Ceramics are brittle; how do they deal with mechanical stress in real-world applications?

Great article, but I would love to know more about the environmental impact of producing these ceramics.

I’m a bit skeptical. How reliable are these ceramics over long periods of use?

Coral-inspired design? Nature really is the best engineer! 🐠

Does this mean we’ll see ceramic fuel cells in consumer electronics soon?

The Monolith sounds revolutionary! How do they ensure quality in manufacturing?

Are there any safety concerns with using ceramics in extreme conditions?

What’s the lifespan of these ceramic fuel cells compared to traditional ones?

I’m curious about the cost implications of switching from metal to ceramic fuel cells.

Can this technology be adapted for use in homes or personal devices?

How does this new technology compare to lithium-ion batteries in terms of efficiency and sustainability?

Fascinating read! How do they prevent the ceramics from cracking under pressure? 🤯

How does this innovation affect the energy efficiency of the fuel cell?

As an aerospace engineer, I’m excited to see how this will impact our industry!

The article mentions 3D printing—how crucial is it to the production process?

Will this new fuel cell design require any changes to existing infrastructure?

How long did it take to develop this technology from concept to reality?

I’m thrilled to see such advancements in sustainable energy! Keep up the great work! 🌍

Are there any other industries, besides aerospace, that could benefit from this tech?

How does the weight reduction influence the overall performance of the fuel cell?

Love the idea of a coral-inspired design! Nature truly is the best engineer. 🌊

This is a game-changer! How do they ensure the ceramics’ durability?

Do you think this will lead to more affordable electric vehicles in the future?

With such a drastic weight reduction, what are the trade-offs, if any?

I’m interested in the role of 3D printing in creating these structures. More details, please!

Does the ceramic material offer any advantages in terms of energy storage?