| IN A NUTSHELL |

|

In a groundbreaking development, engineers from the University of Nebraska–Lincoln have unveiled an innovative self-healing artificial muscle. This technology replicates the self-repair mechanisms found in living organisms, marking a significant leap in the field of soft robotics. By employing liquid metal and heat, this new muscle can autonomously detect and repair damage, potentially transforming industries that rely on durable electronic systems. This breakthrough was presented at the prestigious IEEE International Conference on Robotics and Automation, highlighting its potential to revolutionize how machines handle wear and tear.

Mimicking Biology Through Soft Robotics

Biomimicry has long fascinated scientists, especially the ability to replicate how biological organisms sense and heal damage. Led by Eric Markvicka, the University of Nebraska–Lincoln team has made strides in this area. Traditionally, the challenge has been to develop materials that not only mimic the flexibility and softness of biological systems but also their capability to self-repair. Markvicka’s team addressed this by creating a multi-layered artificial muscle.

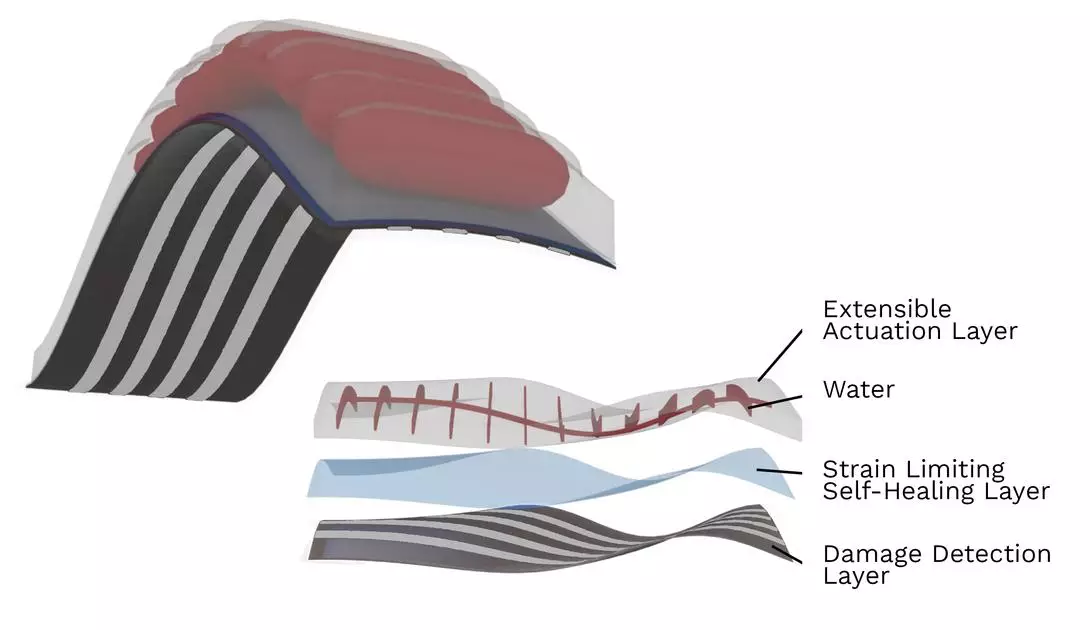

The muscle’s base is a soft electronic skin embedded with liquid metal microdroplets, providing the ability to detect and locate damage. Above this, a robust thermoplastic elastomer layer enables self-healing, while the top actuation layer facilitates movement through pressurization. This innovative combination allows the artificial muscle to respond to damage much like living tissue, making it a significant achievement in soft robotics.

Smart Repair With Built-In Heating

This artificial muscle goes a step further by autonomously initiating repairs. It uses five monitoring currents to detect damage within the electronic skin. When a breach occurs, the system creates a new electrical path, which is then used to generate heat via a Joule heating process. This heat effectively melts and reseals the damaged area, allowing the muscle to heal itself without any human intervention.

Once repaired, the system must reset the damage footprint, utilizing electromigration—traditionally a challenge in electronics. By shifting metal atoms, the team cleverly flips this flaw into a feature, erasing the damage path and making the system reusable. This unique approach not only repairs but also perpetuates the functionality of the artificial muscle, demonstrating a sophisticated blend of engineering and biological imitation.

Flipping a Flaw Into a Feature

Electromigration is typically seen as a negative in electronic systems, often leading to circuit failures. However, the Nebraska team has ingeniously used this phenomenon to their advantage. By intentionally harnessing electromigration, they can erase the damage path, effectively resetting the system for future use.

This approach turns a common electronic failure into a beneficial process, showcasing a novel way to address system longevity and reliability. “Electromigration is generally seen as a huge negative,” Markvicka stated, emphasizing the innovative application of this failure mode. This breakthrough not only extends the lifespan of the artificial muscle but also opens new avenues for electronic miniaturization, where managing electromigration is crucial.

Future Impact in Farming, Wearables, and Waste

The potential applications of this self-healing technology are vast. In agriculture, where equipment often encounters physical damage from natural elements, self-repairing systems could significantly enhance operational durability. Wearable medical devices, subjected to constant movement and stress, could also benefit, leading to longer-lasting and more reliable health monitors.

Moreover, reducing electronic waste is a critical environmental concern. By integrating self-healing capabilities, electronic devices could enjoy prolonged lifespans, reducing the need for replacements and minimizing waste. This advancement could play a crucial role in sustainable technology development, offering benefits that extend well beyond immediate practical applications.

As we embrace these technological advancements, the question arises: How will this self-healing technology shape the future of industries reliant on durable electronic systems, and what further innovations might it inspire?

Did you like it? 4.4/5 (21)

Wow, this is like something straight out of a sci-fi movie! 🤖

I’m skeptical. What happens if the self-healing fails?

Can this technology be applied to human medicine, like healing wounds?

What are the environmental impacts of this technology?

Finally, my phone can stop breaking every time I drop it! 👍

Do these robots feel pain? Just kidding! But seriously, do they?

Any chance this could be used in space technology?

Sounds cool, but how much energy does it consume during the healing process?

“Self-healing” – does that mean no more warranty claims? 🤔

This is the future! Can’t wait to see what comes next. 🚀

Could this tech be dangerous if it malfunctions?

How much does it cost to produce this self-healing material?

The researchers deserve a medal for this innovation! 🏅

Can’t wait to see this in action! When’s the public demo?

Will these muscles be able to repair themselves indefinitely?

Is there a limit to the size of damage it can repair?

Are there any ethical concerns with robots that can self-repair?

Is this tech patented, or will it be open for other researchers?

Just imagine the possibilities! What a time to be alive. 😊

How long does it take for the robot skin to heal itself? Is it instant?

Hope this doesn’t lead to robot world domination. 😱

Does it work underwater or in extreme conditions?

Great, now even robots can avoid going to the doctor! 😂

This is an amazing breakthrough. Thank you to the scientists working on this! 🙌

Will this technology be available for consumer electronics anytime soon?