| IN A NUTSHELL |

|

In a groundbreaking development, researchers are harnessing the power of nature to transform the construction industry. By enhancing the inherent properties of wood, scientists aim to create a material that could potentially replace traditional building materials like steel and concrete. This innovation not only promises to revolutionize the way we build but also offers a more sustainable and eco-friendly alternative. With a staggering 181.5 billion tons of wood produced annually, this abundant resource holds immense potential. Through chemical modifications, experts are unlocking the secrets within lignocellulose, a component found in wood and many plants, to pave the way for a new era in sustainable construction.

Strengthening Wood with Nano-Iron

Researchers from Florida Atlantic University, in collaboration with the University of Miami and Oak Ridge National Laboratory, have embarked on an ambitious project to enhance wood’s properties. Their innovative approach involves the introduction of ferrihydrite, a naturally occurring iron oxide mineral, into the wood’s cell walls. By using a simple chemical process involving ferric nitrate and potassium hydroxide, the team successfully infused this mineral into the wood, creating a high-performance material.

The choice of red oak, a type of ring-porous hardwood, was deliberate. This type of wood is known for its durability and strength. The introduction of nano-scale minerals not only strengthens the wood without significantly increasing its weight but also retains its natural appearance. This method is cost-effective, environmentally friendly, and holds the promise of transforming wood into a viable alternative to steel and concrete in various applications.

Increased Durability of Wood

The incorporation of nanocrystalline iron oxyhydroxide has significantly enhanced the wood’s durability, particularly in its internal structure. Despite these improvements, the wood’s behavior when subjected to bending or breaking remains largely unchanged, ensuring it retains its natural flexibility. The potential applications of this fortified wood are vast, ranging from buildings and bridges to furniture and flooring.

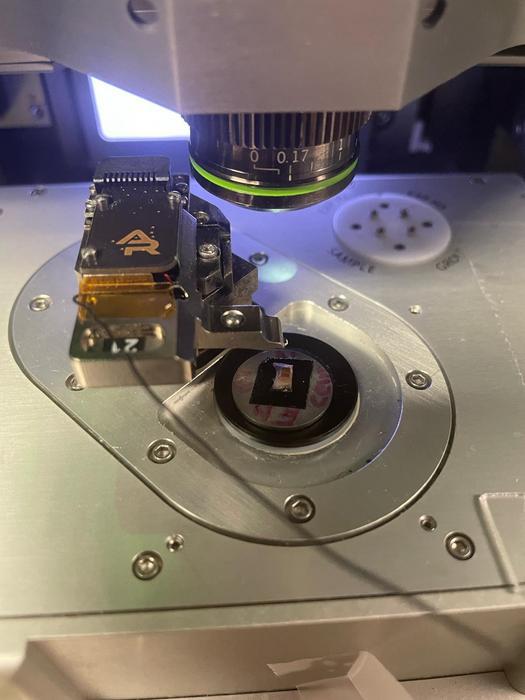

Advanced techniques like atomic force microscopy (AFM) and AM-FM were employed to analyze the wood at a microscopic level. These methods provided insights into the modified cell walls’ stiffness and elasticity, highlighting the material’s robustness. Furthermore, standard mechanical tests confirmed the enhanced properties of the treated wood, solidifying its potential as a replacement for more traditional construction materials.

Environmental and Economic Implications

The implications of this innovation extend beyond the construction industry. As Stella Batalama, dean of the College of Engineering and Computer Science, notes, this development paves the way for a new generation of bio-based materials. The widespread adoption of iron-infused wood could lead to significant reductions in carbon emissions and waste, contributing to more sustainable construction practices.

The economic benefits are equally noteworthy. As a renewable resource, wood is not only abundant but also more cost-effective compared to steel and concrete. This affordability, combined with its enhanced properties, makes it an attractive option for developers and builders looking to reduce costs while adhering to environmental standards. The potential for job creation in the fields of sustainable forestry and bio-materials is another positive outcome of this research.

The Future of Sustainable Construction

As the demand for eco-friendly building materials continues to grow, the innovation of iron-infused wood represents a significant step forward. With ongoing research and development, this material could soon become a staple in construction projects worldwide. The collaboration between universities and research institutions underscores the importance of interdisciplinary efforts in addressing global challenges.

The publication of these findings in the journal ACS Applied Materials and Interfaces marks a milestone in the journey towards sustainable construction. As scientists continue to explore and refine this technology, the potential for its application in various industries is vast. From reducing the environmental impact of construction to improving the efficiency of resource use, the benefits are manifold.

As we look to the future, the question remains: How will the integration of sustainable materials like iron-infused wood reshape our built environment, and what new possibilities will it unlock for generations to come?

Did you like it? 4.5/5 (26)

Wow, steel-like wood? Can it really replace concrete? 🤔

This is amazing! What will they think of next?

Is this material fire-resistant? 🔥

Sounds promising, but how long before we see it in use?

Can we use this wood for furniture too? 🛋️

How does the cost compare to traditional building materials?

Great article, thank you for sharing this breakthrough!

Is this process scalable for mass production?

Steel-like wood? I smell a new superhero origin story! 🦸♂️

This is the future of construction. Can’t wait to see it implemented!

Does the infusion of iron affect the wood’s natural appearance?

Will this new wood be available worldwide?

I’m skeptical. How durable is this material really in harsh weather?

How long does the iron infusion process take?

This could be a game-changer for sustainable building practices! 🌍

What types of wood can be used for this process?

Does the process have any negative environmental impacts?

How does it compare to bamboo in terms of strength and sustainability?

I’d love to see a video of the process!

Could this be used in earthquake-prone areas?

Where can I buy this wood? Asking for a friend. 😅

How does this affect the wood’s weight?

Are there any patents on this technology?

Thanks for the detailed explanation. Very informative!

How does is it affected by water and fire? If burned, wil it toxic to the environment?

What about termite resistance? Is it still an issue?

Can this wood be recycled like regular wood?

Hope this doesn’t lead to deforestation! 🌲

This could make buildings both strong and beautiful!

Is there a limit to how much iron can be infused into the wood?

How does it perform in extreme temperatures? ❄️🔥

Stainless steel wood? I’m intrigued!

Is this tech applicable to other plant materials?

Can this process be reversed if needed?

What happens if the iron starts to rust?

Thanks for the article. Super exciting news! 😊

Does anyone else think this sounds like a sci-fi movie plot? 📽️

How do they ensure the iron doesn’t leach out over time?

Can’t wait to see skyscrapers made from this material!

Bro. We don’t need another chemical process that makes tons of waste and 50 years later there are lawers on TV asking if your doughnut fell out to call them

Does it rust and fire tolerant is it?