| IN A NUTSHELL |

|

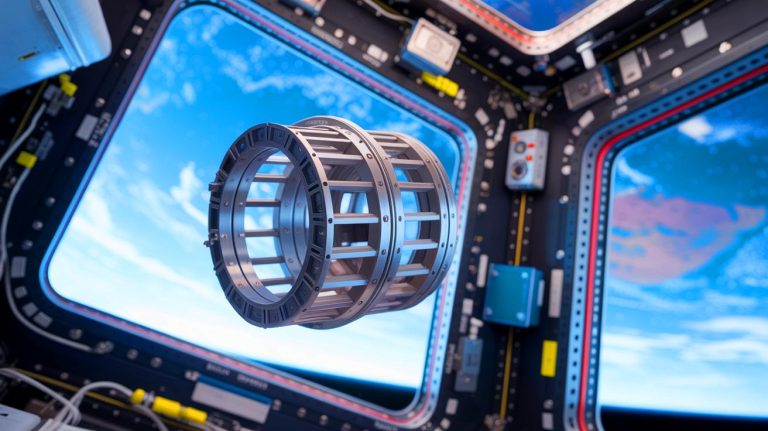

In a groundbreaking achievement, a small metallic object, produced outside of Earth, has captured the attention of scientists at the European Space Agency (ESA). This represents a monumental step forward in space exploration, as it showcases the potential for creating necessary components on-site in space. This innovation, achieved through a collaboration between Airbus Defence and Space and the ESA, involves the use of a metal 3D printer aboard the International Space Station (ISS). The implications of this technology are vast, potentially changing the way we approach long-term space missions and the development of infrastructure in orbit.

The First Metallic Object Made in Space

The ESA has recently made history by bringing back to Earth the first-ever metallic object created entirely in space. Utilizing a sophisticated metal 3D printer, developed in collaboration with Airbus Defence and Space, the object was fabricated aboard the ISS. This pioneering achievement was made possible through the installation and operation of the printer by astronaut Andreas Mogensen in the Columbus module. The printer initially completed a test print in the shape of an ‘S’ curve before successfully producing two complete samples. This remarkable milestone demonstrates the evolving capabilities of 3D printing technology, highlighting its potential for enhancing autonomy in space missions.

The successful production of these metallic samples marks a significant advancement in the field of space technology. By understanding how microgravity affects the 3D printing process, scientists can refine this technology for future missions. The ability to create tools and components on-demand in space could drastically reduce the reliance on supply missions from Earth, paving the way for more sustainable and independent operations in the cosmos.

The Role of Microgravity in 3D Printing

One of the critical areas of investigation for ESA scientists is the effect of microgravity on the 3D printing process. Unlike on Earth, where gravity aids in the deposition of materials, space presents unique challenges. In the absence of gravity, the behavior of metal powders used in 3D printing changes significantly. Special systems are required to manage and direct these powders precisely, ensuring accurate and reliable production of components.

The technology employed in space is similar to terrestrial 3D printing techniques, involving the use of a laser to melt metal powder layer by layer to create solid objects. However, adapting these techniques for use in microgravity involves considerable innovation in both materials and design. This adaptation is crucial for the development of future missions, where on-demand production of parts could provide immense logistical and economic benefits.

Implications for Future Space Missions

The successful implementation of metal 3D printing in space holds transformative potential for future space missions. By enabling the in-situ production of spare parts and tools, space missions can become more self-sufficient, reducing dependency on Earth-based resupply missions. This self-sufficiency is particularly vital for deep space exploration missions, where resupply from Earth is not feasible due to distance and cost.

Looking ahead, the successful analysis and application of this technology could lead to more ambitious projects, such as the construction of entire structures in orbit. These advancements could revolutionize how we think about space infrastructure and exploration, making long-term habitation and exploration more viable. Additionally, this technology exemplifies the power of collaboration between space agencies and industry leaders to push the boundaries of what is possible in space exploration.

Challenges and Innovations in Space-Based 3D Printing

While the potential benefits of space-based 3D printing are immense, the technology is not without its challenges. Developing printers capable of operating in the harsh conditions of space requires significant innovations in design and materials. The systems must be robust enough to handle the unique environmental factors of space, such as radiation and extreme temperature fluctuations.

Furthermore, the precision required to manage and manipulate metal powders in microgravity necessitates cutting-edge technological solutions. Despite these challenges, the ability to produce components on-demand in space represents a significant leap forward in space technology. By sending digital plans from Earth, astronauts can manufacture necessary items as needed, reducing the logistic burden of carrying a large inventory of spare parts.

In the final analysis, the advent of metal 3D printing in space is a testament to human ingenuity and the relentless pursuit of progress. It raises important questions about the future of space exploration: How will these advancements change our approach to colonizing other planets? Will this technology unlock new possibilities for human habitation beyond Earth?

Did you like it? 4.4/5 (28)

Wow, this sounds like it’s straight out of a sci-fi movie! 🚀

Are they sure it’s not just a piece of space debris? 🤔

Fascinating article! Thanks for sharing this incredible discovery. 🙌

Thanks for keeping us informed about these exciting developments in space tech!

This is a game-changer for future Mars missions, don’t you think?

How does the cost of space-based 3D printing compare to launching items from Earth?

It is likely much more expensive,unless the Earthside-made parts are also printed-the immediate and HUGE advantages of printing in situ are rapid replacement and those associated with avoiding needing a large parts inventory. Launch costs for raw materials might be a little less since,but actual production costs will be determinate.

Are they planning to print bigger objects in the future?

Seems like we’re one step closer to living like The Jetsons! 🛸

What kind of metal was used for the 3D printing process?

Is it possible for these 3D printers to malfunction in space?

Malfunction of any device is never impossible.

I’m amazed by how far technology has come. Great read!

Wasn’t there a similar project attempted before?

Does this mean we can build space stations entirely in orbit one day?

How do they control the metal powders in microgravity? Sounds tricky!

Do they plan to use this technology for building lunar bases?

Looks like the future is now. Amazing! 😍

Are there any environmental concerns with this new technology?

What are the potential applications of this technology on Earth?

This will make resupplying missions so much easier and cheaper!

When will we see this tech being used on a large scale in space?

Does this mean we’ll have space factories soon? 🏭

I’m not sure I fully understand how this works. Can someone explain?

This could really change the way we think about space travel.

How does microgravity affect the quality of the printed objects?

I hope they keep us updated on future developments!

Such an exciting time for science and exploration! 🌌

What other materials can be used for 3D printing in space?

Are there any safety concerns with having a laser in space?

Can’t believe we’re printing objects in space now. Mind-blowing! 🤯

Sounds like the beginning of a space-based manufacturing industry!

How long did it take to print the metal object in space?

Isn’t it risky to print metal objects in space with all the debris floating around?

So cool! Can’t wait to see what they’ll print next. 😄

I’m skeptical. How can they be sure it’s not from Earth?

These comments look mostly AI created. The title of this article is misleading. It’s not a bad article, so why do you guys need to cheat?