| IN A NUTSHELL |

|

In a world increasingly burdened by environmental challenges, the quest for sustainable materials is more critical than ever. The introduction of a new, fully biodegradable material derived from the mycelium of the split-gill mushroom marks a significant breakthrough. This innovative material not only offers tear-resistance and functional versatility but also achieves these properties without chemical processing. Developed by researchers at Empa’s Cellulose and Wood Materials laboratory, this living bioplastic could potentially revolutionize multiple industries by replacing traditional, environmentally harmful materials.

Built by Nature, Fine-Tuned by Science

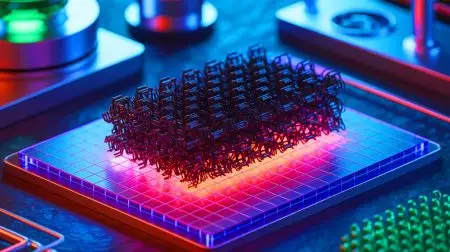

The fascinating world of mycelium is at the heart of this scientific breakthrough. Mycelium is a network of fungal filaments that forms the vegetative part of a fungus. Typically, it undergoes chemical processing to enhance its properties, often compromising its ecological benefits. However, the team at Empa has managed to leverage mycelium’s natural properties without such interventions. Using the extracellular matrix produced by the fungus, which consists of proteins and polysaccharides, they have developed a material that is both strong and biodegradable.

The team selected a specific strain of the split-gill mushroom, rich in schizophyllan and hydrophobin. These compounds play a crucial role in reinforcing the structural integrity and functionality of the material. As Ashutosh Sinha, an Empa researcher, points out, this mycelium acts as a living fiber composite. The synergy between nature and science in developing this material is a testament to the untapped potential of living materials.

Living Fibers for Films, Emulsions, and Beyond

This new material is not just limited to being a biodegradable alternative to plastic. It presents a myriad of applications, particularly in the form of films and emulsifiers. The mycelium films exhibit excellent tensile strength, making them suitable for replacing plastics in packaging and compostable products. The potential for such films in reducing plastic waste is enormous.

Moreover, the material’s unique ability to stabilize emulsions makes it a valuable asset in industries such as cosmetics and food. Hydrophobins, the protein found in the mycelium, stabilize oil and water mixtures, and the emulsion becomes more stable over time—a rare attribute in emulsifiers. The living material’s capacity to enhance product stability over time could redefine standards in these industries.

Breakthrough air-powered tech claims to recycle 94% of plastic in just 4 hours using moisture

Sustainable Electronics and Eco-Friendly Sensors

Beyond packaging and emulsification, the potential applications of this living mycelium material extend to the realm of sustainable electronics. The material’s responsiveness to moisture makes it a promising candidate for developing eco-friendly sensors. Imagine sensors that can biodegrade after fulfilling their purpose, thereby minimizing electronic waste.

The researchers are also exploring the possibility of creating a biodegradable battery with electrodes made from this living fungal paper. Such innovations could pave the way for a new generation of environmentally friendly electronic devices, aligning technology with sustainability.

A New Era of Biodegradable Solutions

The implications of this research go beyond material science. It represents a paradigm shift in how we approach sustainability and material usage. By harnessing the inherent properties of fungi, scientists are challenging conventional materials and offering a more sustainable alternative. This innovation holds the promise of reducing our reliance on chemically processed materials and mitigating the environmental impact of conventional plastics and other non-biodegradable substances.

As industries explore these new possibilities, the question remains: How will this groundbreaking material transform the landscape of sustainable solutions, and what further applications could emerge as we continue to innovate with nature’s own tools?

Did you like it? 4.5/5 (26)

Wow! This is mind-blowing! Could we really see this material in everyday products soon? 🤯